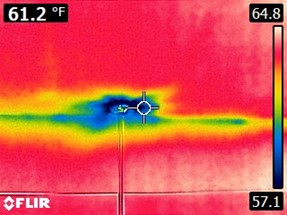

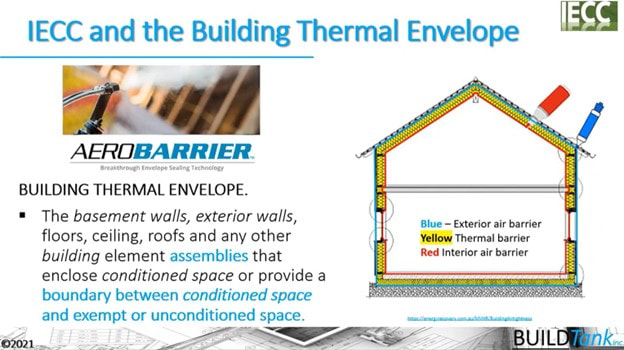

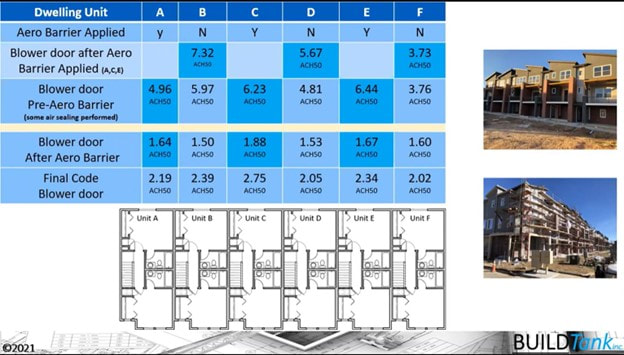

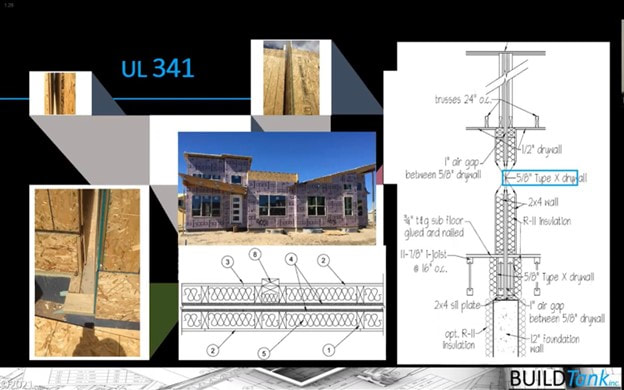

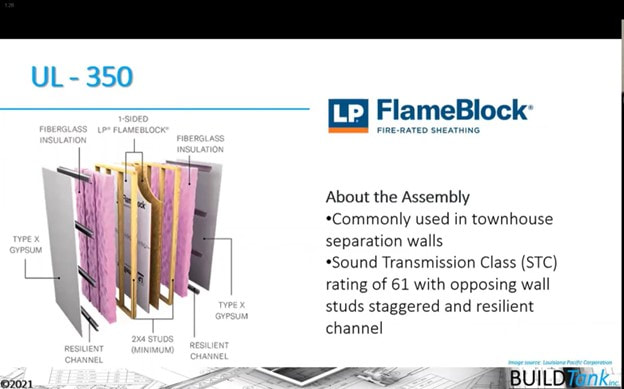

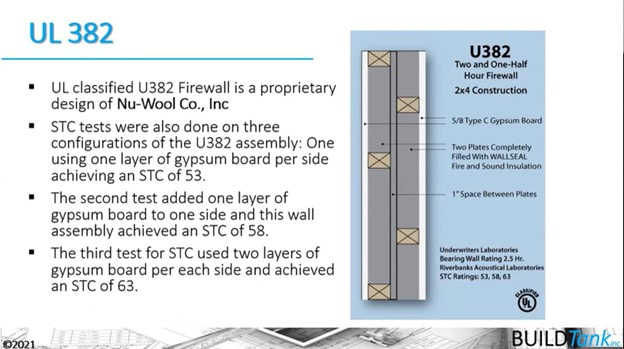

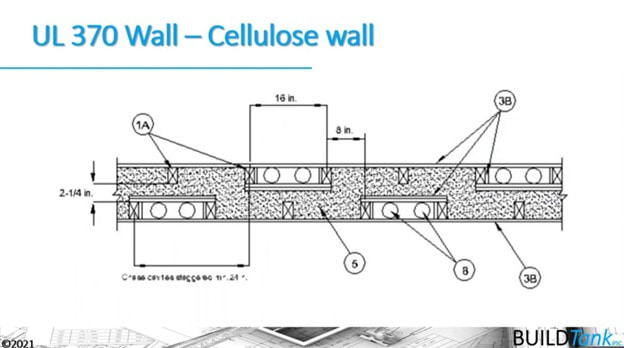

Why Do Townhouses Keep Failing Blower Door Tests?Energy Auditors, LLC has been doing blower door tests on new homes for over 10 years and it is common knowledge that townhouses and duplexes tend to perform more poorly than single-family homes. But why is that? We have done some research to get to the bottom of this. We are indebted to Robby Schwarz, founder of BUILDTank, Inc., for much of information below. A link to his research can be found at the end of the article. The IssueThe most common type of adiabatic wall used in new construction homes today was designed generally to optimize fire safety rather than air tightness. While fire safety is clearly important, air tightness is becoming increasingly important as the energy code has become more strict in the last few years. Shaft walls are frequently constructed with metal “C” and “H” channels holding drywall two thick sheets of drywall. This forms a relatively air-tight, continuous shaft completely separating the two homes. The adiabatic walls are then typically finished by installing a 2x4 wall on each side of the shaft wall. Drywall is installed on the 2x4 wall. A ¾” gap is left between the finish wall framing and the shaft wall to prevent heat transfer in the event of a fire. The problem is that this gap is usually open to the attic, allowing unconditioned air to enter the interior wall. This means that the vast majority of the air leakage at the adiabatic walls is not coming through the walls from the adjacent unit, but into the wall assembly around the perimeter edge of the principal townhouse unit. In order to effectively air-seal the wall, this gap must be addressed. Complicating the situation is that some code officials do not permit any air sealing of adiabatic walls because they believe it could reduce the effectiveness of the fire safety measures. This makes the typical air-sealing solution unavailable, and as a result, these townhomes may have trouble passing an air infiltration test for energy code compliance. Typical Solution: How to Air Seal Shaft WallsIndustry experts have determined that sealing the perimeter edge of the shaft wall at this ¾" gap is the key to sealing these adiabatic walls. Spray foam is typically used for a sealant. Where the shaft wall is constructed with “C” channels back-to-back, those seams should be sealed with caulk. This method should dramatically reduce adiabatic wall leakage. It requires copious amounts of spray foam due to the size of the gaps, but is a simple solution to perform. We recommend verifying the insulator's work as it is all too common for this task to be done hurriedly and with too little sealant. AeroBarrier Solution and Its Effect on TownhomesAeroBarrier is a new technology that works by pressurizing the home and spraying an aerosolized sealant throughout the interior. The pressure forces the sealant to flow through holes in the air barrier which causes the sealant to coagulate and seal the holes. This procedure must be done right after the drywall is installed in the home. During the application process, the fan and sprayers can be run for as long as needed to achieve the level of tightness the builder desires. The longer the system runs, the tighter the home gets, assuring that the home will be able to meet air infiltration requirements. AeroBarrier works by sealing the Red Interior Air Barrier line shown below.AeroBarrier is a new technology that works by pressurizing the home and spraying an aerosolized sealant throughout the interior. The pressure forces the sealant to flow through holes in the air barrier which causes the sealant to coagulate and seal the holes. This procedure must be done right after the drywall is installed in the home. During the application process, the fan and sprayers can be run for as long as needed to achieve the level of tightness the builder desires. The longer the system runs, the tighter the home gets, assuring that the home will be able to meet air infiltration requirements. AeroBarrier works by sealing the Red Interior Air Barrier shown below. A common misconception is that a row of townhomes can be air-sealed by having AeroBarrier applied to every other dwelling unit, but one builder found that this is not the case. Sealing every other unit did very little to improve the blower-door scores in the unsealed units but sealing all units in the row dramatically improved the scores (See graphic below). This helps to prove that the primary pathway for adiabatic wall leakage is not from unit to unit, but from each unit individually through the shaft wall system itself. Alternative Shaft Wall Construction MethodsIt seems as though the current adiabatic wall design is not the most intuitive since its design ignores air sealing. But there are many other approved shaft wall designs that are more efficient from an energy standpoint and a material cost standpoint. Construction methods, load capacity, R-value and sound transmission may also need to be considered. One example is the UL 341 (or U341) which consists of two 2x4 walls with drywall on both sides of each individual wall and a 1” gap in between the walls. Another method is UL 350 which is similar to UL 341 but has a new product called LP Flame Block in the center instead of drywall. It also uses resilient channel between the framing and drywall for a higher STC rating. UL 382 is a proprietary design featuring two 2x4 walls with a 1” gap in between and the walls are filled with Nu-Wool's WALLSEAL fire and sound insulation. UL 370 is built with two staggered rows of 16" o.c. 2x4 studs that are spaced 2 ¼“ apart and the whole cavity including the stud rows and the gap in between, is filled with cellulose. UL 370 would provide the greatest insulation R-value out of all these options. ConclusionThere are multiple ways to air seal townhouses enough to satisfy the energy code without forfeiting fire safety. As noted, there are many considerations in choosing a wall system and many good options other than the one most commonly used. Each of these options has pros and cons. Of those discussed here, AeroBarrier is likely the simplest method. Manually air sealing shaft walls can be effective as long as fire safety is taken into account. Air sealing alternative shaft wall designs such as UL 341 and UL 350 would be basically the same as the standard design, while UL 382 and UL 370 might look a little different. No matter what method you choose, it can be done effectively, and Energy Auditors LLC is ready to help you do it. Works Cited

Robby Schwarz. “Creating an Airtight Shaft Liner Area Separation Wall” Build Tank Inc. resnet2022.virtualbyvario.com/vod/nzc-15-creating-an-airtight-shaft-liner-area-separation-wall/

0 Comments

Leave a Reply. |

Archives

August 2023

Categories |

© 2015-2022 - Energy Auditors, LLC - All Rights Reserved (717) 914-8155 - [email protected] - Dillsburg, PA

RSS Feed

RSS Feed